Simulation of ball charge and liner wear ScienceDirect

Radziszewski, S. Tarasiewicz I Simulation of ball charge and liner wear ... 22 P. Radziszewski and S. Tarasiewicz, Modelling and simulation of ball mill wear ...

WhatsApp)

WhatsApp)

Radziszewski, S. Tarasiewicz I Simulation of ball charge and liner wear ... 22 P. Radziszewski and S. Tarasiewicz, Modelling and simulation of ball mill wear ...

Simulation of Size Reduction in Ball Mills ... in the UFRJ mechanistic modeling approach to tumbling mill ... about the simulation of the wear of ...

Modelling and simulation of ball mill wear . It is assumed that ball mill wear occurs in each of three comminution zones, with ...

ball mill modelling using cfd3jtravels. modelling and simulation of ball mill wear .Take a look at Equipment''s large inventory of unused and used ball mills.

Official FullText Publication: Modelling and simulation of ball mill wear on ResearchGate, the . representation of the dynamic interaction and the effect. of ball.

Modeling on the Effect of Coal Loads on Kinetic Energy of. Jul 9, 2015 measuring and controlling the coal load of a ball mill is key to (a) Simulation model of ball ...

official full text publication modelling and simulation of ball mill wear on possibility of optimizing ball mill performance while including the wear rate factor.

MODELLING AND SIMULATION OF GRINDING . MODELLING AND SIMULATION OF GRINDING CIRCUIT IN MADNEULI COPPER CONCENTRATOR ... Calibration of a ball mill model is the ...

Modelling and simulation of ball mill wear . Wear, 160 (1993) 309316 309 Modelling and simulation of ball mill wear P. Radziszewski" and S. Tarasiewicz5 ...

Dynamic Simulation of Size Reduction Operations from ... The Ball Mill Feature 1 ... realistic wear and replacement models

Official FullText Paper (PDF): Modelling and simulation of ball mill well as the power draw of the grinding system. As. a result of the highly stochastic.

Official FullText Publication: Modelling and simulation of ball mill wear on ResearchGate, the professional network for scientists, In the present article, ...

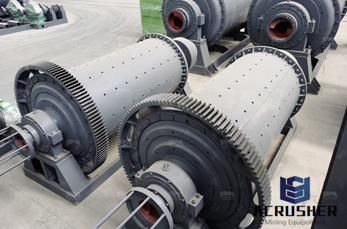

Modelling and simulation of ball mill wear , In the mineral processing industry, ball mills are used to reduce ore from one size distribution to another Ball mill ...

Feed Back. Read Readbag users suggest that is worth reading. The file contains 208 page(s) and is free to view, download or print. Chat Online

In the mineral processing industry, ball mills are used to reduce ore from one size distribution to another. Ball mill wear occurs as a result of the violent ...

Official FullText Publiion: Modelling and simulation of ball mill wear on ResearchGate, the professional work for scientists. » Learn More

See discussions, stats, and author profiles for this publication at: https:// net/publication/ Modelling and simulation of ball mill wear

Simulation of a ball mill operating with a low ball . Simulation of a ball millThe objective of this paper is to determine the mills optimized condition for the first ...

Modelling and simulation of ball mill wear , Modelling and simulation of ball mill wear, This model has been added to a ball charge motion model allowing the ...

ball mill wear rate specifications Modelling and simulation of ball mill wear ResearchGate. It is assumed that ball mill wear occurs in ...

Modelling and simulation of ball mill wear INIST. It is assumed that ball mill wear occurs in each of three comminution zones, with adhesive wear found in the ...

Discrete element modelling (DEM) of particle flows inside ball mills involves ... segregation and wear in ball mills using ... for the simulation of ball mills. ...

Modelling and Simulation of Ball Wear | Mill . Modelling and Simulation of ... zones and abrasive wear arising in the grinding ... for sizing wet tumbling mills ...

Wear, 160 (1993) 309316 309 Modelling and simulation of ball mill wear P. Radziszewski" and S. Tarasiewicz5 ''Dartement des sciences appliqus.

WhatsApp)

WhatsApp)